PLAGE.com.pt

UNIDEMI

ENTIDADE SCT

UNIDEMI is a research centre of the Portuguese Foundation for Science and Technology (FCT). Current UNIDEMI full members are mostly coming from Mechanical & Industrial Engineering Department (DEMI) of the Faculty of Science and Technology of the New University of Lisbon (FCT/UNL); the other members coming from different higher education schools located close to Lisbon. DEMI was created in 1999, but its scientific areas - Mechanical and Industrial Engineering - were active at UNL since the FCT/UNL foundation, which occurred thirty years ago (1977). In 1999 the Mechanical and the Industrial Engineering areas merged, having emerged DEMI. Currently, DEMI integrates 40 teaching staff (75 % holding a PhD degree and 25 % an MSc).

UNIDEMI is hosted by DEMI and was created in 2003. They share secretarial staff, facilities and Laboratories. The Department offers undergraduate and postgraduate programmes (MSc and PhD) in Industrial Engineering and Management, and in Mechanical Engineering. It also offers specialised postgraduate programmes (e.g., Project Management, Occupational Health and Safety). By the end of 2008, there were about 700 students involved in these programmes.

UNIDEMI is responsible for stimulating scientific research, developing advanced training programmes, and supporting the Mechanical and Industrial Engineering community. UNIDEMI's performance was rated as "VERY GOOD" by the 2008 international evaluation commissioned by Portuguese Foundation for Science and Technology (FCT)

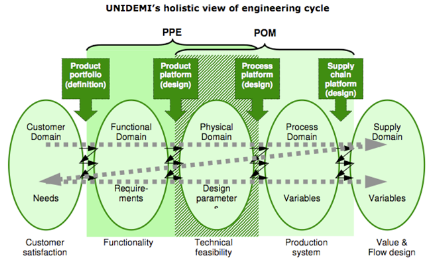

The UNIDEMI's scope is the holistic development of products and processes. Therefore, UNIDEMI activities focus on this subject, according to the following scheme, where a new organisational structure is based on two research groups:

1. Product and Process Engineering (PPE)

2. Production and Operations Management (POM).

UNIDEMI approach is oriented toward the consideration of the whole product or process life cycle - product definition, design, development, production, supply chain design, distribution, operation, and disposal (including re-cycling and dismantling) - and the improvement of the corresponding management and control processes.

PPE Group mostly focuses on the design cycle, while the POM Group is more associated to the operation cycle. The Product and Process Engineering Research Group.

PPE integrates researchers from different areas of knowledge with the aim of developing methods, models and methodologies related to different aspects of integrated product and process development, which can enhance the product and service lifecycle performance. The methods are related to capture customer's needs and its transformation into engineering requirements and constraints, selection of design solutions, technologies and manufacturing systems, embedment of manufacturing knowledge into design, and products and processes measurement and control, in order to achieve variability reduction and to allow for

evaluating the functional features in terms of performance and added-value. In fact, it has been recognised that design, development, and production engineering activities have to be carried out in parallel, which stresses the need of integrating as much as possible the several existing approaches and techniques.

The main research lines of PPE are:

- Research on Quality Engineering methods, such as Total Quality Management (TQM), Design of Experiments and Taguchi Methods, Metrological Control, Statistical Process Control, Reliability and Six Sigma, so that they can be used not only in continuous improvement of existing products/services but also at the design and development stages of new ones.

- Research on Axiomatic Design theory and its combination with other methods, such as Concurrent Engineering, DFM /DFA, GD&T, Design of Experiments and DFSS (Design for Six Sigma).

- Research on non-traditional manufacturing processes, such as press formed semi-solid aluminium alloys, high speed and micromachining, and hybrid processes (ultra sound/laser/machining).

- Research and development of on-line control systems based on models combining statistical techniques with neural networks or knowledge based systems.

- Research and development of capability maturity models, integrating quality systems standards and TQM into an Axiomatic Design framework to define capability levels and their interrelationships, starting at the strategy defined by top management (abstract level) towards the product or service marketing and delivery (detail level), to provide products/services with added-value to the customer.

- Research on integration of the various methods into models to define roadmaps for promoting timely and cost-effective lean processes.

The research findings will be validated through applications, including real case studies in industrial companies.

The Production and Operations Management Research Group

POM researchers are focused on productivity issues, operations improvement and optimization.

To deal with actual increasing market changes and uncertainty, it is necessary to design new lean management systems and robust processes, and to develop an understanding of complex supply chains in which vulnerability is integrated. The integration and coordination between business operations, organisational design, information systems, and intellectual capital, production and logistics management activities are becoming critical.

The main objective of the POM Group is to develop a management support system prototype to assist managers in case of organization instability, as a result from continuous (un)expected disturbing occurrences. POM strategy integrates different knowledge areas in the group, at two levels:

The first level concerns to the creation of a basic, qualitative framework to assure effective strategic deployment and integration of organisational design issues. Researchers are expected to contribute for the development of business models for supporting both interoperable networked enterprises and e-government interoperability to provide resilient supply chains (e.g., addressing both business oriented industry and, government and non-profit agencies, as for example in healthcare management). The researchers think that the development of strategic foresight models, to understand the process of creating value, and

UNIDEMI - R&D Unit in Mechanical and Industrial Engineering, Universidade Nova de Lisboa, Portugal the development of frameworks for assessing and determine the value of companies intangibles (like intellectual capital), will provide important input for the research.

The second level involves the modelling and testing process; it includes a test bed approach to simulate quantitative model behaviour of the production and logistic system, including the interaction with the supply chain. The management support system prototype is intended to integrate a simulation model for supply chain studies, which will allow for analyzing contingency plans in Production and Operations Management, i.e., production, inventory, procurement and service and distribution strategies. We expect to design a specific web site to provide the chance to use the model and the management support system prototype, for

resilience evaluation and benchmarking purposes.

In conclusion, the group intends to contribute for the creation of a lean and agile management environment in the supply chain, using Systems Modelling & Simulation techniques, as well as Information Engineering Management, as tools for organisation modelling and development. The research findings will be validated through applications, including real case studies in industrial companies and public services.

The main research lines of POM are:

- Research on Project Management methods, such as Critical Chain Project Management and new approaches for time buffer sizing, to optimize projects time and costs, and minimise risks involved in the launching of new products/services and projects.

- Research on new Production Paradigms and Strategies, such as lean and agile resilient systems, combining decision support tools, simulation and other quantitative techniques to investigate improved or optimized solutions in production planning and control and cost engineering.

- Research on Supply Chain Management addressing eventual problems (uncertainty, disturbances and risks) derived from market globalization, which may affect its performance; in addition a sustainable development induces an environment care on the disposal and re-cycling of products which justifies further research on reverse logistics.

- Research on Managing Organizational Design from the point of view of operational productivity, such as business process management and management by processes, combining the integration of different management systems in areas such as quality, environment, health, safety or logistics management.

- Research on Information Engineering and Interoperability, integrating strategic foresight methodologies with business intelligence and intellectual capital to achieve higher standards on knowledge engineering capability.

Both PPE and POM cooperate with other researchers, participate in networks with other scientific institutions and foster the research internationalization